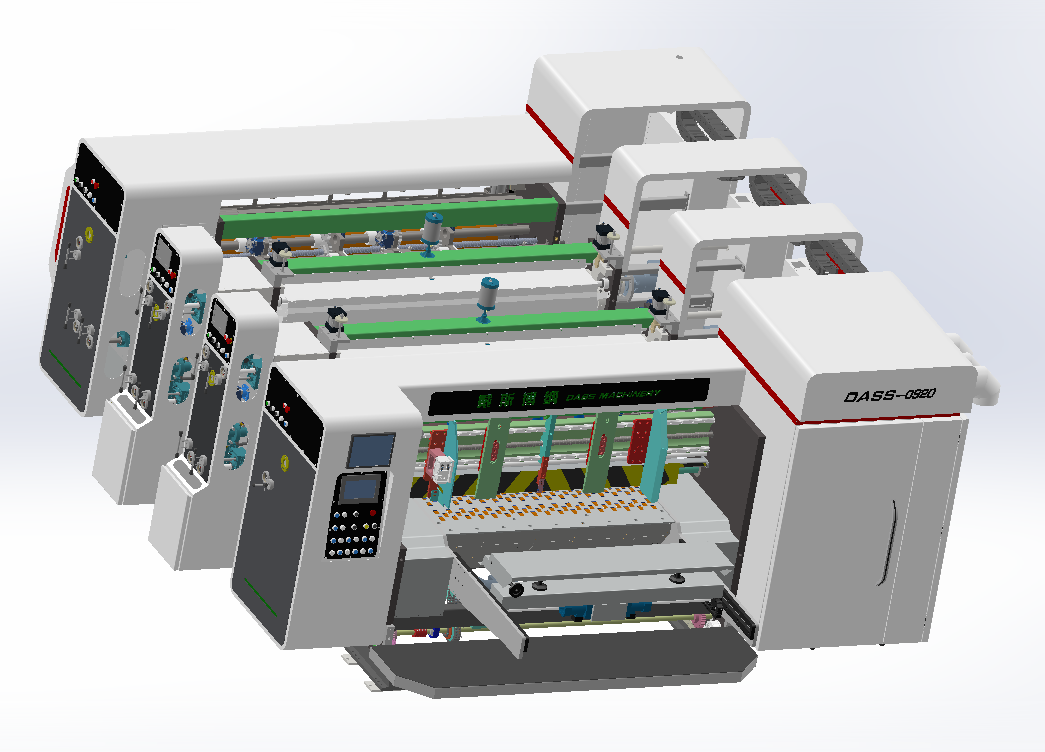

型伺服免压前缘双色水墨印刷圆压圆模切机

Type 1222 Servo-driven Pressure-free Front Edge Two-color Water-based Ink Printing Rotary Die-cutting Machine

Main Technical Parameters

Function Introduction of the Printing Unit

-

Memory and return to the original printing position function: Automatically records the relative position of each color print before shutdown when the printing plate is cleaned and the printing roller is rotated.

-

Surface grinding and chrome-plating treatment of the printing roller

-

Made of high-quality steel, with surface grinding and hard chrome plating. Static balance calibration ensures stable operation and adapts to high-speed running.

-

Reference lines are engraved horizontally and circumferentially on the roller body for easy plate alignment.

-

Worm gear infinitely variable plate rolling shaft: Suitable for standard plate hanging strips to realize quick plate change.

-

Electric 360° forward and reverse adjustment of the printing roller with digital automatic display of the adjustment value.

-

A foot switch is installed to control the forward and reverse rotation of the plate mounting cylinder, facilitating plate changing.

-

Automatic zero reset function.

-

Electric axial adjustment of the printing roller.

-

Pneumatic diaphragm pump: Features simple operation, convenient maintenance and stable ink supply.

-

Circulating pneumatic ink feeding with automatic water-based ink cleaning.

-

Filter screen filters out impurities to ensure printing quality.

-

Phase adjustment mechanism: All phase adjustments adopt this mechanism.

-

Unique planetary gear structure allows 360° adjustment both during operation and shutdown.

-

Digital display screen for printing phase adjustment.

-

Automatic reset system after plate cleaning.

-

Phase fixing system

-

Electromagnetic clutch brake device: The original meshing point of the transmission gear remains unchanged during unit clutch or phase adjustment.